About Us

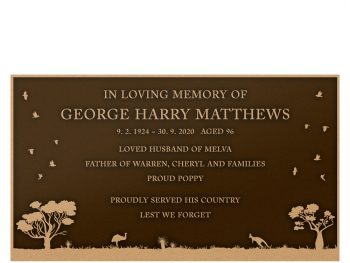

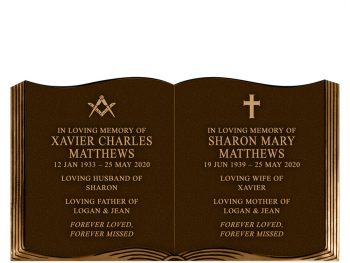

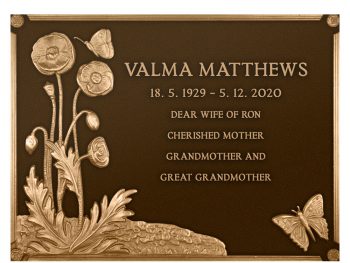

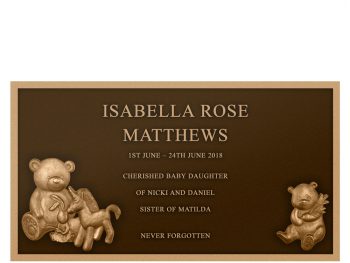

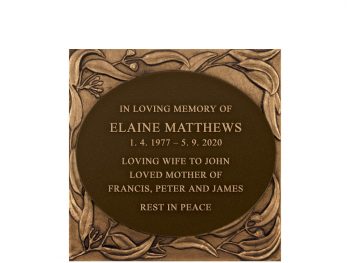

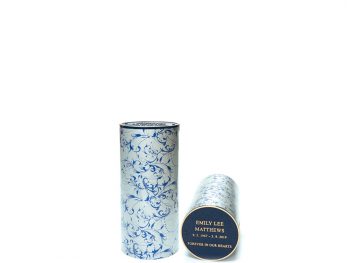

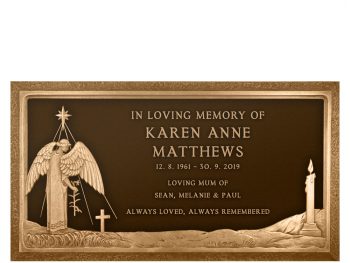

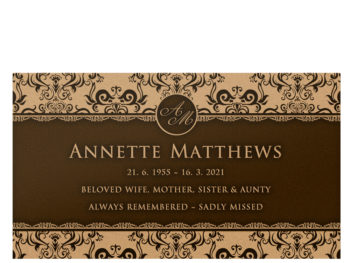

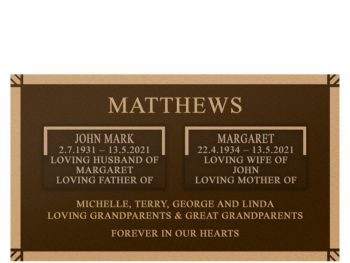

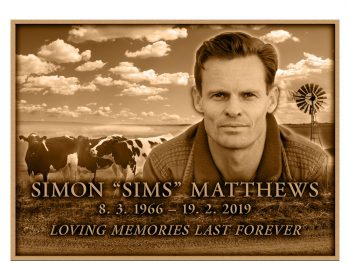

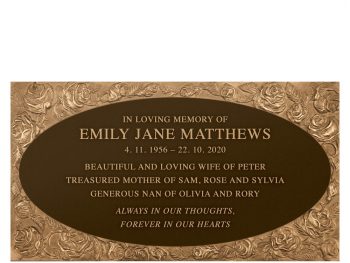

We are the oldest, most experienced and leading foundry in Australia, casting Bronze and Aluminium plaques, lettering, badges, crests, insignia, donor products, interpretive signs and directional markers.

About Us

We are the oldest, most experienced and leading foundry in Australia, casting Bronze and Aluminium plaques, lettering, badges, crests, insignia, donor products, interpretive signs and directional markers.

About Us

We are the oldest, most experienced and leading foundry in Australia, casting Bronze and Aluminium plaques, lettering, badges, crests, insignia, donor products, interpretive signs and directional markers.

Arrow Bronze has a long and rich history in Australia.

Since the early 1920’s the Barr Brothers had developed and honed their skills in fine engraving.

In 1940, they established K&R Barr General Engravers and Metal Workers. From humble beginnings, this company would become the foundation of a business producing Australia’s finest bronze memorial work.

Over the next 60 years, the company became known for its craftsmanship and its commitment to quality and innovation.

Today, Arrow Bronze is the market leader in the design and production of Memorials and has become the most trusted brand in the category.

The company’s commitment to quality and relationships has never wavered and is built into the DNA of the organisation as well as the incredible staff that represent Arrow Bronze.

Our range of memorials is unsurpassed and our commitment to innovation and technology ensures we stay ahead of the pack.

We also service the growing Architect and Design sector with creative and innovative uses of Bronze in the construction of buildings, signs and a variety of other applications.

We have a state of the art production facility and we are proudly Australian Made.